@alexaseleno

The automotive parts industry has undergone a significant transformation over the past few decades, driven by advancements in technology and shifting consumer demands. According to a report by Research and Markets, the global automotive parts market was valued at approximately $1 trillion in 2022 and is projected to reach $1.5 trillion by 2027, reflecting a CAGR of 6.5%. This dramatic growth is largely attributed to the integration of cutting-edge technologies, including electrification, automation, and lightweight materials, which have redefined the roles and functionalities of automotive parts.

Traditional components are giving way to innovative solutions that enhance performance, safety, and sustainability. As the automotive sector continues its evolution towards digitization and advanced manufacturing processes, understanding the trajectory of automotive parts—from conventional designs to sophisticated, tech-driven solutions—becomes crucial for stakeholders aiming to remain competitive in this rapidly changing landscape.

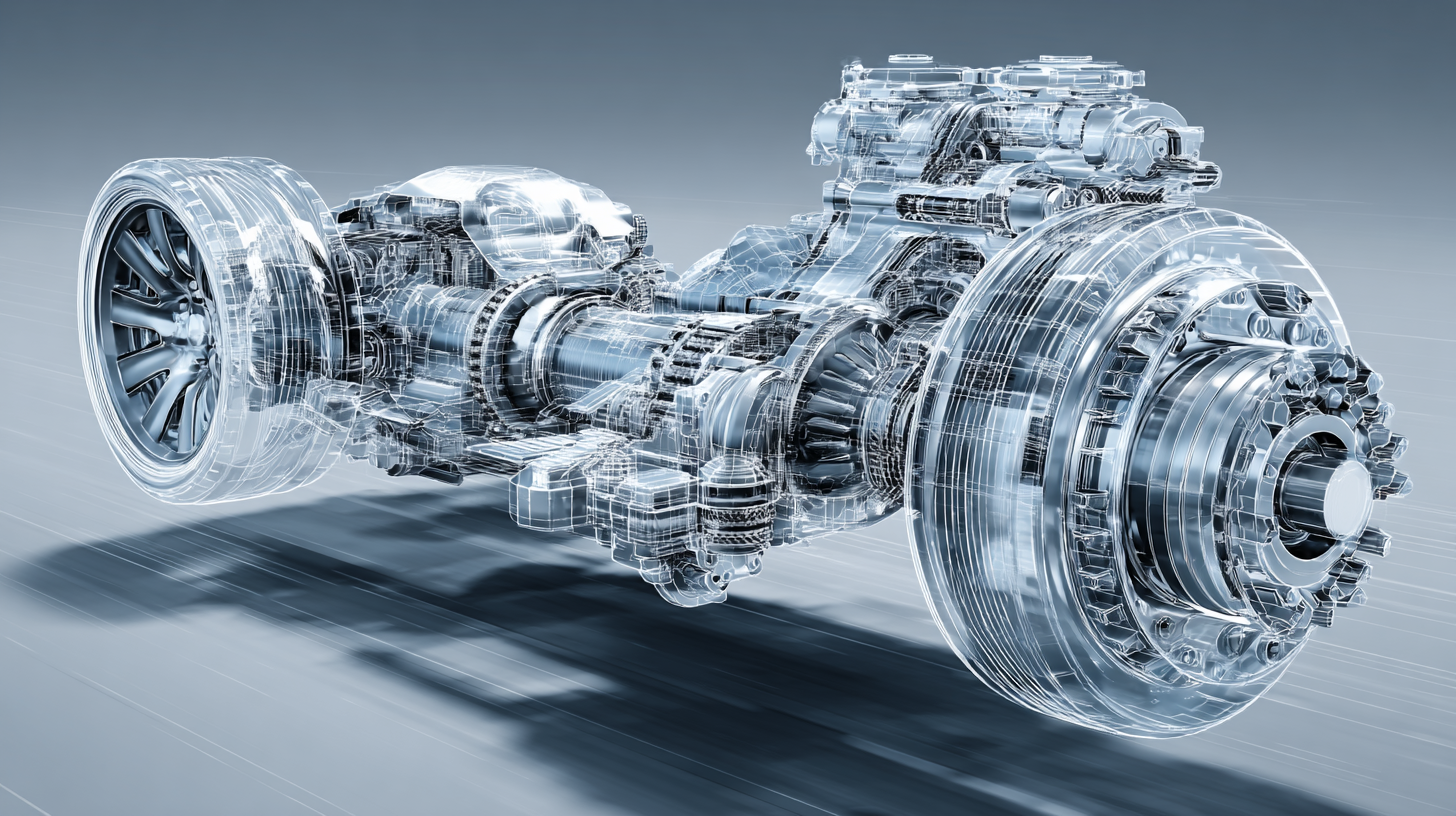

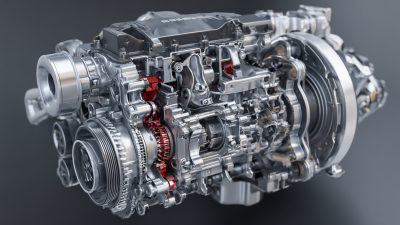

The evolution of automotive parts has progressed significantly since the inception of the automobile in the late 19th century. Initially, vehicles were constructed with simple components made from wood and metal, focusing mainly on functionality. Innovations such as the introduction of the internal combustion engine in the early 20th century transformed the landscape of automotive design, leading to the adoption of more complex parts like the drive train and suspension systems. These advancements helped improve performance and ride comfort, marking the beginning of a shift toward more specialized automotive components.

As the automotive industry continued to evolve, the mid-20th century saw the rise of mass production techniques, such as Henry Ford's assembly line. This period facilitated the widespread availability of cars while also prompting advancements in part manufacturing. The introduction of synthetic materials and composites in the latter part of the century allowed for lighter, more durable components, enhancing fuel efficiency and safety. Today, with the integration of cutting-edge technologies like smart sensors and electric drivetrains, automotive parts are not only more efficient but also capable of communicating with one another, paving the way for a new era in automotive engineering and design.

The automotive industry has undergone significant transformations, particularly in the materials used for vehicle parts. Traditionally, steel and aluminum were the primary choices owing to their strength and availability. However, as manufacturers sought to improve fuel efficiency and reduce emissions, the focus shifted towards advanced composites. These innovative materials, such as carbon fiber and thermoplastics, offer remarkable strength-to-weight ratios, allowing for lighter vehicles without compromising safety.

Transitioning to advanced composites not only enhances performance but also opens avenues for design flexibility. Unlike traditional materials, composites can be molded into complex shapes, enabling engineers to create more aerodynamic and aesthetically appealing components. Additionally, with the integration of smart materials that can adapt their properties in response to environmental conditions, vehicles are becoming more efficient and responsive. As automotive manufacturers embrace these advanced materials, the evolution of automotive parts signifies a crucial step toward sustainable mobility and cutting-edge innovation in the industry.

| Material Type | Common Applications | Advantages | Challenges | Future Trends |

|---|---|---|---|---|

| Steel | Frame, body panels | Strength, availability | Weight, corrosion | Lightweight alloys |

| Aluminum | Wheels, engine components | Lightweight, good thermal conductivity | Cost, strength compared to steel | Advanced alloys, better recycling processes |

| Plastic | Dashboard, bumpers | Moldability, cost-effectiveness | Durability, UV stability | Biodegradable options, composites |

| Carbon Fiber | High-performance cars, racing | High strength-to-weight ratio | Cost, manufacturing complexity | Automated production techniques |

| Composites | Body panels, structural components | Lightweight, versatility | Recycling, material integration | Increased adoption in mainstream vehicles |

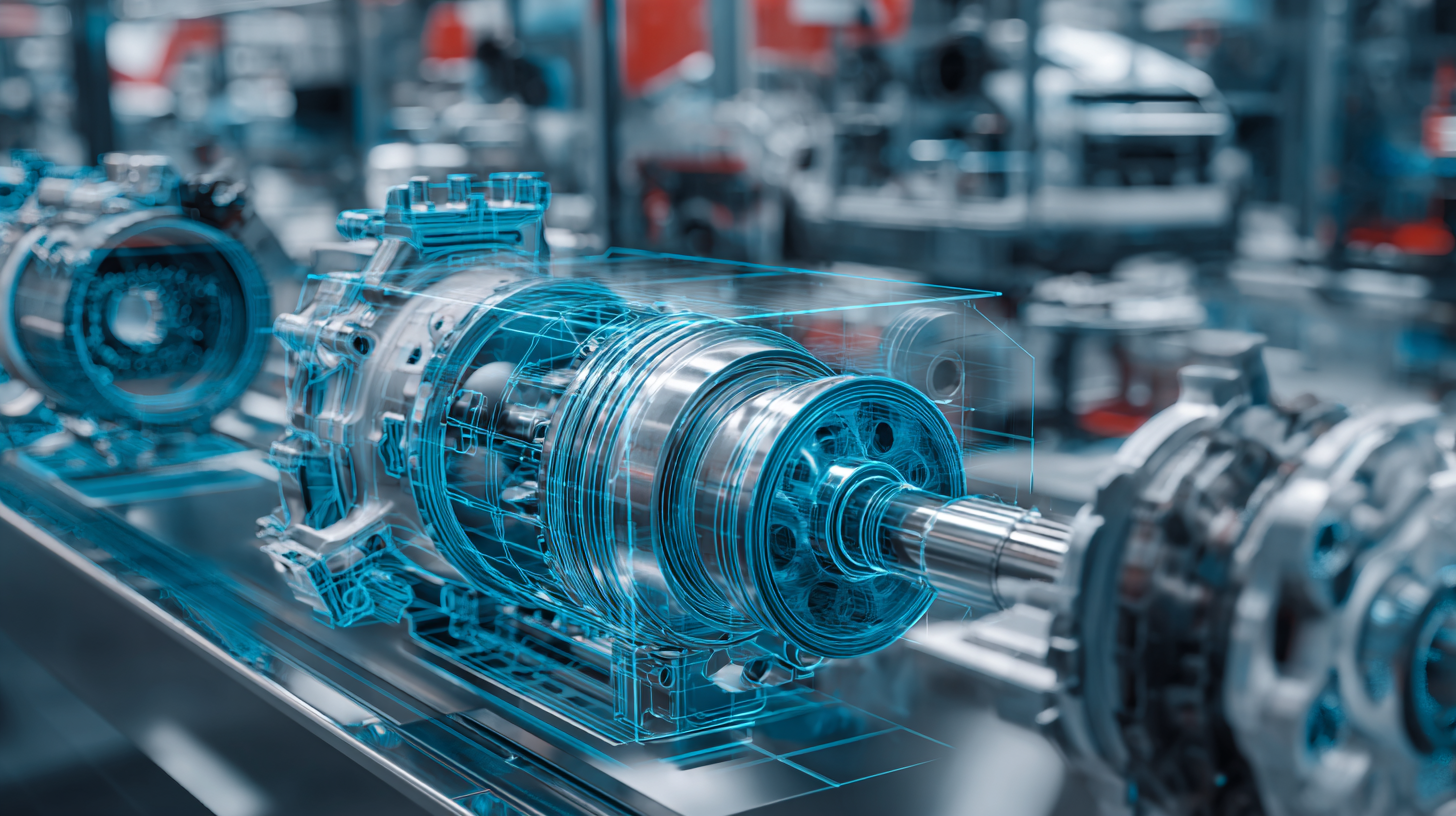

The automotive industry has undergone a significant transformation, with digital technologies playing a crucial role in the development of automotive parts. Advanced technologies such as 3D printing, artificial intelligence, and the Internet of Things (IoT) have changed traditional manufacturing processes. These innovations enable manufacturers to design parts that are lighter, stronger, and more efficient, optimizing performance while reducing costs. For instance, 3D printing allows for rapid prototyping, enabling engineers to test and iterate designs quickly, which has considerably shortened the development cycle.

Moreover, the integration of digital technologies enhances the precision and personalization of automotive components. With the use of AI and machine learning, data-driven insights can be harnessed to forecast trends, inform design choices, and improve supply chain management. IoT connectivity permits real-time monitoring and maintenance of parts, leading to longer lifespans and improved reliability. As the automotive landscape continues to evolve, the convergence of these technologies not only streamlines production but also fosters innovation, paving the way for a new era of automotive excellence.

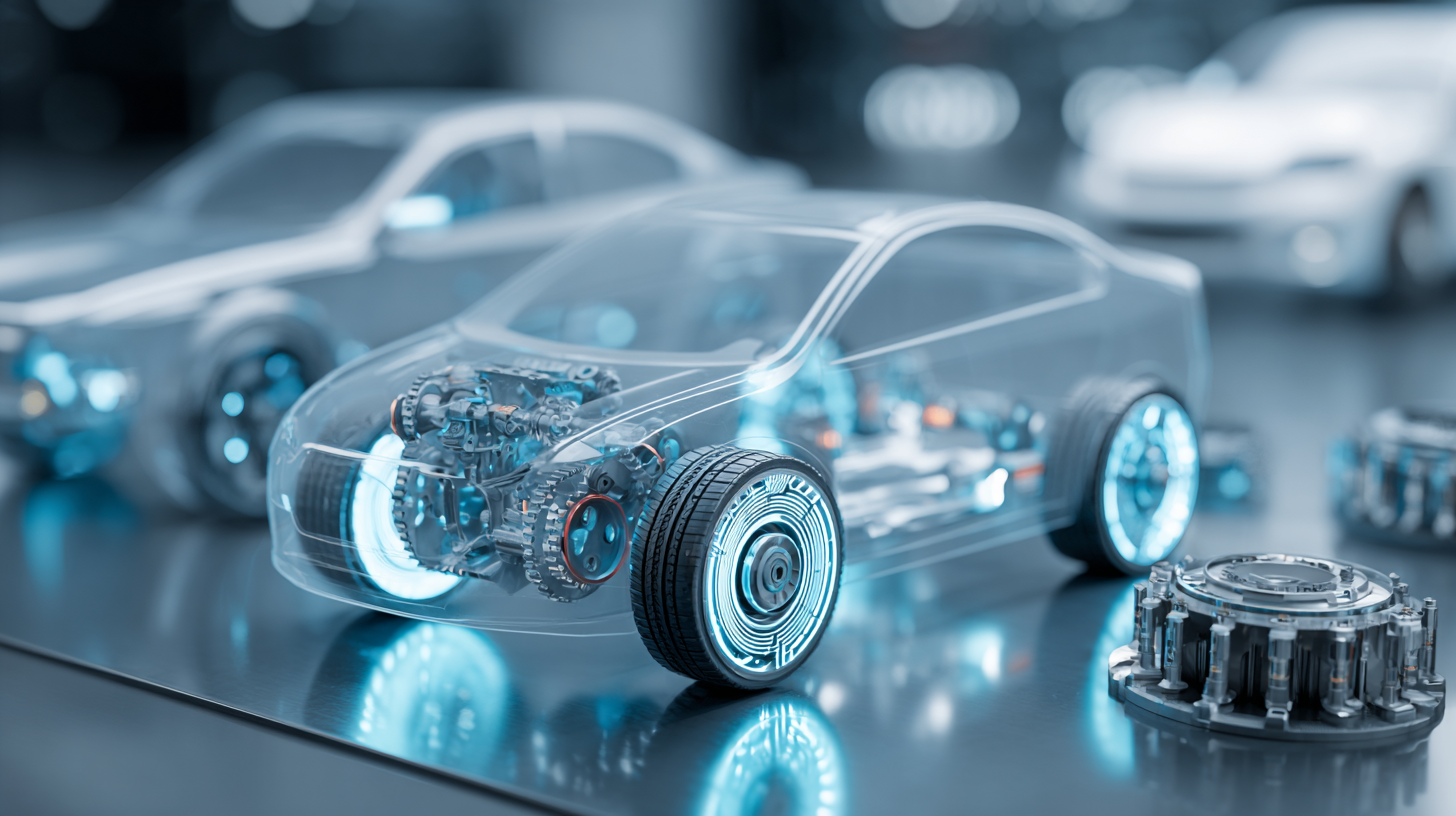

The automotive industry is undergoing a significant transformation, driven by the emergence of smart and connected components. With global market projections indicating the automotive audio market will grow from $1.1 billion in 2025 to $1.81 billion by 2032, a compound annual growth rate of 7.2%, it is clear that innovation in vehicle technology is accelerating. Smart factories are a crucial part of this evolution, with automated systems efficiently producing finished products every two minutes to meet increasing customer demands.

Additionally, the integration of advanced technologies, such as “neural networks” in electric vehicles, highlights the critical role of harness safety. As vehicles become smarter, ensuring the reliability of electrical harnesses is paramount for driving safety, with every malfunction posing significant risks. The necessity of prolonged communication between engineering teams and clients further emphasizes the bespoke nature of modern automotive parts, tailored to meet specific standards while fostering the growth of smart, interconnected vehicles. This intricate interplay of technology and safety considerations marks a pivotal shift in how automotive components are designed and manufactured.

The automotive industry is undergoing a significant transformation driven by

sustainability trends that are reshaping the manufacturing of parts.

According to a report by Grand View Research, the global green automotive market is expected to reach

USD 1 trillion by 2025, reflecting the rising demand for eco-friendly practices.

This shift not only emphasizes the need for materials with a lower environmental footprint but also presses

manufacturers to innovate with sustainable processes.

For instance, the adoption of recycled materials and bio-based composites is becoming prominent in vehicle production,

reducing dependency on fossil fuels and lessening landfill contributions.

Moreover, the implementation of advanced manufacturing technologies such as

3D printing and smart manufacturing is enhancing

sustainability in automotive parts production. A report by McKinsey highlights that 3D printing can

reduce waste by up to 90% in certain production processes.

Companies are embracing these technologies to streamline operations and improve efficiency while lowering

their carbon footprint. This innovative approach not only caters to

consumer demand for sustainable options but also positions manufacturers competitively in an

increasingly eco-conscious market, ultimately paving the way for a

greener future in automotive manufacturing.

© 2025 Grandmark International. All rights reserved.

© 2020 Grandmark. Grandmark International. All rights reserved. Proud shareholder of Temot International.